Table of Contents

To-Do

Spring 2016 (sale)

Finish re-wirefinish runs, bundle all togetherpanel, auto-pilot, water pump, mast lamps, bundle for nav light switchesscrew down NMEA T's

remove old fuse box- move house battery forward

- cable runs to second house battery

remove old cabling

- New bracket for mast-head lamp

- Cleanup & paint, new contact cement for some of the wallpaper

- Varnish bulkhead (fill screw holes with wood putty)

Spring 2015

Install deck plate for chain lockerDONE!repair sail covernew curtains, fix-up curtain rods- add switch for paralleling relay control?

- Find good insulation and storage bins to re-do ice box

- make styrofoam cutter with soldering iron & wire & coping saw?

new diaphragm bilge pump install (done save clamps, two wood screws, and something to hold output hose from shaking)Move cooker gimbals forward in the box, outwards on the sides (thinner boards for mounts), and mount the cooker and pot holderDone!Drill Ikea mixing bowls for pre-heating cups on cooker, cut them down by 1.5cm vertically to fit- Add mixing bowl below water separator/fuel filter

Fall 2014

Re-wire:

At some point, when all is ready, rip out the old wiring for everything except cabin lampsEnlarge holes for wire runs- Cut and hinge panels for main settee seat boards for easier access

Move radio below shelf & handset to starboard sideMeasure & install opening panel with latch for breaker panelsInstall breaker panelsInstall large fuse holders (by battery switches or by breaker panels? by battery switches)Large but not battery cable sized cable run to breaker panelsInstall lugs and bus bars behind breaker panels for panel connectionInstall single pair runs for each device (est. run length = 42,5m !):Top lantern (3.5m)Motor lantern (3.5m)Deck lights (3.5m)Compass lights (10m)Water pump (6m)Cold storage compressor (already have the run w/extra length)Cabin lights (1m)NMEA 2000 Bus (no run needed)VHF power (no run needed)- Panel power (should maybe install bus bars or water proof connectors in panel?) (4m)

Tiller pilot/auto pilot (4.5m) - straight run back, skip the junction box in the engine compartmentBilge pump (3.5m)12v Accessory ports (3m)

Install new switches in lamp switch panel (picked up some awesome old metal toggles from Tackel & Tåg- Fit new bilge/accessory port switch plate

- Install new 12v port near main battery switches for search lamp

- New wiring (new connector?) for tiller pilot

Batteries:

- Install 3 boxes, two consumption boxes just under quarter berths aft of bulkheads, one starter box further aft starboard side

- New cables for two battery bank

Cold-storage re-work:

Move compressor to lower unused locker- Remove middle shelf

- Add another insulation layer all around

- Re-do plastic lining

- ?

Heater install:

- Need carbon monoxide detector

Fashion a deck ringCut hole in deck and mount flue vent/deck ring- Mount flashing/heat shield - maybe not necessary

Mount heaterMock up flue pipeWeld up flue

Other:

- Get a bulkhead mount compass, or re-fill the old compasses and install those on the bulkheads? (Ritchie BN-202 Navigator looks lovely, but two would be outrageously expensive)

- Re-fill and install original Sestrel compasses on the cockpit bulkheads? May need lower teak wedges to get a better viewing angle

- Re-glass various small spots:

- Main bulkhead near mast foot

- Below-board bulkhead forward of engine

- New cable and through-hull fitting for short-wave antenna cable?

Spring 2014

- CO detector

& heating install (deck cap teak ring) Seacocks & gummi box

get some OARS!Done, 150dkk oars achieved!

Rudder stuffing box repair:

re-tap stuffing box holecut rod for stuffing box boltsstuff new packingcut off pintle boltsprimecharge batteryclean threads on shaft

Spring 2013

grease gummy box -grease rudder stuffing box (possibly loosen & check fittings)grease cockpit drain sea-cocks -replace shaft anode -clean prop & rudder shaft -engine check-upcheck keel, scrape & prime -check through-hulls & ball valves -anti-foul -light primer -charge & bring battery back to the boat -- do we paint the topsides? probably not…

to buy:

light primeranti-foulzincgrease

Summer Holiday

Install foam & box for cold storage? Install compressor? Only if we have a second battery, and maybe on the way?Just needs finishing touches.Install battery switchswitch mounted - to do: wiringMeasure battery cables, make replacements for all necessary connections in diagramInstall second battery & battery boxesCheck/replace coolant anode - bought replacement anodeCheck for Volvo spares- esp. relay and impeller, oil filter, fuel filter- o-rings & filter for water separator, coolant anodeboughtInstall curtain rods & curtains - mostly done, going to make 4 new brackets for the middleReplace the anchor (best available option is likely the Kobra 2, 16kg Palby stock# 01.1776 and only ~1200dkk) or Rocna for 5000dkk!?!?Get anchor holders for Danforth & Bruce?Got at least some pulpit guards for temporarily hanging anchors front or backGet heavy duty canvas chain bag(s) for stern lockerFound thick rubber/recycled tire bagsInstall anchor lamp rotary switchDone, pain in the ass since the lamps are all using a common ground. Had to hastily run a new cable.Get longer chain rode (find out what we have first) - had 3.5m 10mm chain, ordered 25mchain on boat in bagGet longer rope rode and shackleswe had a longer rode in the stern locker, picked up two 10mm shacklesInstall life-raft bracketwooden bracket leveled off and metal bracket attached w. hose clamps - need to trim one side of attachments before finishing installationReplace the broken reefing block - need to measure the track - 25mm - purchasedReplace the spinnaker slide - also need to measure the track - 32mm x 6 - purchasedBlock primer tubes (plastic padding? solder brass caps into the tank leads mounts?) on the paraffin cooker- doneGet funnel for stove fuel- done - made a brass funnel from sheetInstall chain to hold cooker12v lighter-socket USB portInstall NMEA 2000 bus to panel switchMake male-to-male NMEA 2000 connector to extend the bus via a drop-cableMake mag-safe charging cable for targus adapter (“Targus 90w AC/DC Pro: Smart tip S4^ and “3rd Gen Magsafe cable” Air: Smart tip S6 or S7 and “3rd Gen Magsafe cable” http://pangea.stanford.edu/~schmitt/magsafe/)IT WORKS!Stop mail deliveryGet software togetherOrder and install chain pipe (http://www.toplicht.de/en/shop/anker-und-ketten/kettenrolle-ketteneinlauf-und-kluese/ketteneinlaeufe/ketteneinlauf-oval-bronze-spartan) - ordered, arrived, too afraid to install.Deck plate installed.

Hull/Spring-launch

to-do to get mast up

- clean, sand, and varnish bulkhead

adjust forestay turnbuckle so it's equal on both ends (it's integral to the furler, so can't see it, need to remove line, turn the buckle completely off, then tighten it a few turns againskipping this.fix delaminated shroud/chain-plate boardused construction adhesive & screws, not the same as epoxy, but likely good enough considering how bad it wasdrill drain holes in mast foot boxsingle hole drilledre-attach shrouds and staysattach spreader end-covers (cable ties? white line? self-amalgamating tape?)find material to put beneath mast foot to raise height- strong plastic? cheap cutting board maybe?tin spreader wiring if there's timereplace topping lift line with halyard and add external topping liftcheck mast wiring is goodfix stiffness on forestay turnbuckledrill drain hole in mast footclean spreader lamp fixtures w/wd-40attach bracket on port spreader for flagsre-wire spreader lamp fixtureswire was good enoughshorten below-deck conduit bracket and use only 1 nutoil sheavesget self-amalgamating tape and apply to jib halyard cable splicere-wire motor lamp fixtureinstall masthead lampcut new wooden foot blocks from something, any solid wood for nowinstall conduit with hole mid-mast for spreader and motor wiringThat wasn't much fun.run nmea 2000 cable, mast-head cable, vhf cablere-run halyards since they had to be pulled to get the conduit in right

the rest

cut & hinge cockpit table so it can fold to a smaller sizedouble-clamp all hoses & tubing (nearly there, engine intake finally has double clamps! 26/7/2012)- replace deck-level cockpit drain tubing and clamps

- install motor insulation (some done)

- touch up motor insulation with foil tape

- scrape & paint keel bolts

replace & reseal windows- must REDO one window due to acetone spill -we need to get new bolts, some galvanized were used, 20 bolts each.- reseal all deck/cockpit hardware and rails (some day)

- add ball valve to exhaust through-hull?

- add ball valve to bilge through-hull?

- clean and paint bilges (lots of cleaning done, sludge removed from area forward of the rudder post, engine area, main bilge)

- re-join slight split in bulkhead joint near mast

- find and repair the soft spots- how bad is it? Confusing. Found approximately

50soft spots today - panic-driven mis-count, more like35a dozen spots of interest?, some of which were miss diagnosed or not urgent, the outlook is still good. Hull thickness is approx. 9/16ths (14+mm) without gel-coat.Sanding them out tomorrow, begin filling on sunday.Filled, need sanding, then priming. re-install VHF N-connectortin mast light wiring endsmeasure tubing for head & cockpit drains- - 1.5in/38mmreplace cockpit drain tubing and clamps can replace cockpit drain tubing in the water?- fitting is 1.5in/38mm diameterboom! major drain tubing done, only need to replace the deck level stuff. painful job but will probably sleep a little better.paint topsides?won't happen this seasonnew ball valves where necessarynot necessaryreplace speed log through-hull w/ tri-ducerneed to grease and insert the unit in the new through-hull fittinginspect & grease stuffing boxgrease ball-valves if necessaryall seem wellreplace prop-shaft zincgrease propcharge batteryre-install battery, ensure motor cranks overre-install tiller just for launchspot prime & anti-foulmaybe re-grease cock-pit drain sea-cocks- they were serviced mid-last season, still a lot of grease present

Mast

extend mainsail track down to boom or replace it - ours is 7/8th - finally found a source for the old stuff: http://www.rigrite.com/Hardware/Track/Sailtrack.htmFinally did this with just a flat piece of sheet metal cut to the right width and riveted on stand-offs- the new sail made this a necessity to allow us to use our existing cover. In cock-pit reefing next?replace spinnaker slidegot lazy and bought the cheapo one - make one from scratch and save 600dkk for a crappy one- connectors would be nice for the spreader lights- maybe gold-plated headphone male & females? another season…

install conduit inside mast (was fix cables inside mast to something, they sway too much)can use rivets via assembling the conduit, drilling hole in mast, inserting conduit, marking it, removing it, then drilling. repeat, ensuring previous holes are lined up by inserting a screw/nail/rivet/whatever in each.Went with: “Otherwise stainless threaded rod bent in wide U's can be used to seat the conduit against one forward quarter.”need good rivets to re-install mast footneed good cable for lightingfound some thick-jacketed marine cable, 1.5mm conductormaybe need N-connectors for VHF antennacould use stainless threaded rod, bent 90 degrees to clamp the conduit in 4 places, can line up where holes should be at the top.This worked.silvan has a 1” inner diameter industrial garden hose, seems like it might be perfect. i think it's 15m in length.Used 1“ drain pipe in 2m sectionsmotor lamp and spreader lights need a second run.Run in the same conduit, ran cables first, then pulled through the mid-mast entries while feeding the conduit into the mast.

re-wire lighting cables to include anchor light, replace other aging cablesinstall new led anchor/nav combo lightreplace foot blocks, they're rottenreplace topping lift linedrill-out/replace spinnaker adjustment point (knob broken, screw seized)

Rigging

widen holes through “german solution” and spray rail to reduce friction on main & spinnaker halyards- adjust halyard exit sheaves to roll better (main & topping lift sheaves rub together), maybe replace with something like this

install new backstay adjusterinstall block on out-haulnot great, but there and workingreplace reefing blocks25mm block replaced the broken one- run reefing lines to cockpit

- run topping lift line to cockpit

- run out-haul to cockpit

- install secondary winch in place of compass

Sails

repair tear in mainsail(new sails in 2013)re-attach jib UV cover(new sails in 2013)repair zipper on lazy pack where it's separating

Engine

- replace fuel-injector sleeve o-ring

Electric/Instrument

- consider using garmin NMEA 2000 connectors for mast lamp wiring- they're waterproof and available:

repair engine instrument panel warning lights, switches, and alarmreplace masthead lamp with tri-color & anchor LED fixturewire masthead switch for tri-color vs. whitereplace motor lamp with LED- hell, replace all lamps with LED

need gas solonoid(NA), nav lights, engine light, anchor light, spreader lights, instruments, auto-pilot/aux, cabin lights, water pump (that's 10 so far)replace main battery switch w/ 2-battery systemadd house battery- move battery to enclosed battery box, under starboard berth, forward of the bulkhead

- move battery(ies) to engine area? maybe build a shelf just below the storage area?

replace lamp cables in mastand install waterproof connectors rather than use terminal strips- for cheaper fuse panels, consider circuit breaker inserts from Mouser, otherwise probably use expensive 4 panel breakers

General

move gas line, it's currently snaked around. should be along the deck or hull the entire stretch (drill a hole in the bulkhead rather than route to the space that's there)bought paraffin cookerre-do gas locker installation- the container is mounted too high (ISO standard is a minimum of 3” clearance above the at-rest waterline fully loaded, we're way above that), does not have a gasket or latches to seal the lid, and has two fittings outside the locker (one valve at the stove, one joint to copper near the locker) where leaks would drain into the boat. it may be best to build in a suitable locker with space for fittings and gauges.bought paraffin cookerinstall gas solenoid shut-offbought paraffin cookerinstall gas gaugebought paraffin cooker- clean & paint bilges

- install new hose for the head, install new anti-syphon loop

move tools to tool bag instead of boxrevarnish table- revarnish all over

re-sew spray hood windows- repair fiberglass at traveller end points & install stops

drill hole in mast foot to allow drainage into bilgelengthen/add loop to secondary bilge pump linedeemed not necessarysew new curtains andinstall new curtain rodsreplace instruments?panel mount Garminperhaps add hidden padlock?- convert old winches to internal ratcheting? would need to replace bottom center gear with 3 or 4 small ratchets (pawls I think?) instead… need to sketchup something first. basically the idea would be to cut off the gear from the shaft, and install 4 pins with 4 pawls.

remove side lantern mounts on pulpitremove stern lantern & mount from stern railremove stern lantern cabling- remove wall paper, glue, oil teak, re-vaneer where necessary

shorten starboard quarter berth and install nav deskwon't bother- make two cushions for cockpit table

replace seal on instrument panel, maybe replace the entire enclosure with a custom boxnot necessaryadd chain locker in the bow? could be a complicated modification, could use a bronze port into the lower area with little more modification than cutting a hole- repair hatch

- repair hatch seal

& add pins to closing shackles - re-glass ventilator boxes

repair/replace ventilatorsget ventilator coversremove lobstersand & varnish tillerinstall depth sounder (create 4“ diameter flat spot in front of keel using epoxy)not necessary, old log replaced with sounder log combo

Winterize 2011

Winter

engine

Top up tankReplace coolant with 50/50 coolant water mixPump coolant/water mix through sea water systemChange oilOmitting since it was changed mid seasonRemove impeller & inspectImpeller is goodChange fuel filterEmpty water separatorSpare o-rings and filters purchased and installed. There was dreaded “bug” gunk in the filter, but after “sampling” at least from what flows out of the tank, I think we may be okay. I need to sample from inside the tank of course with a syphon… (so says Nigel Calder.

Spring

engine

- Clean, dry & paint

Check anodes- Fresh water cooling anode was completely gone, nothing but powder, it has been replaced- Maybe get a clear/easier to see through over-flow/coolant bottle

Get spare relay- Check thermostat

Check temp sensors if possibleThey work!Check & likely replace AlarmAlarm is now working.

on-going

- change oil & filter - done 9/7/2011

- change oil & filter - done 15/7/2012 - this time only the recommended amount of oil was added, 1.4 ltr. I ignored the dipstick mark, the level is 3/4 to the start of the depression on the stick. The oil has stayed clear for longer; I think we had much too much in the previous season (and prior to our purchase)

Stuffing Box

- grease gummy “stuffing box” (done 8/4/2012)

I learned a lot I think the morning of 17/04/2012 when Clan went back in the water. The stuffing box I had greased was letting water pour in at a pretty alarming rate, and if I pushed or prodded the rubber around water flowed in more like the rate of a faucet. My inspection and grease the week before was apparently quite inadequate. I managed to slip grease in by pinching and sliding the end of a cable/zip-tie loaded with marine grease in, then un-pinching and sliding it back out. About an hour of doing this and the water came to drips, and not long after that, stopped all together.

Done:

- replace water tank (maybe a smaller tank or a hard tank would have been better)

- mount water pump

- mount deck organizer to better route main & spinnaker halyards back to cockpit

- un-seize current backstay adjuster

- remove old stereo

- remove old cables from bilge

- patch leaks in jib traveler bolts

- patch leak in spinnaker boom deck support

- replace caulk/filler at shroud & stay chain plates (used sikaflex)

- move last jib reefing block up on stanchion to reduce wear

Equipment needed:

life ring&man overboard light&throw lineflares, 3 white, 3 parachute?LED Lampsthe important lamps are now all LED- panel mount compass

es(danforth saturn dual-read) - a single compass in the instrument box? - for jib conversions, Harken Unit 0 uses #6 (6/32” or 5 mm) luff tape: www.sailmakerssupply.com or www.sailrite.com or sailcloth.co.uk

ice box

Currently we have a crappy electric cooler, which if I've done the math right, uses more battery (around 4 amps for a new one) than a real compressor.

The Isotherm units look okay: specifically the Classic Compact 2005/6

Tempo has the 2006, a larger plate than the 2005, for 3500dkk. They also have a køleskab kit with insulation etc, for 1270dkk. An expensive pair, but it will allow us to make use of a space we can't currently reach (sealed off behind the stove), and allow us to get more space by getting rid of the giant cooler.

Silvan has this "super EPS" insulation, very cheap, but only in 140mm thickness (too thick). They also have the cheaper stuff, which is probably perfectly adequate.

For running off of shore power, a battery charger with at least 5 amp capacity (more is obviously better) is recommended.

Found one person's from-scratch installation on a Marieholm 26, here.

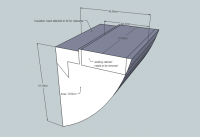

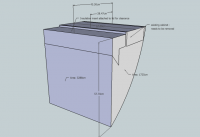

Because of the very narrow opening for the locker (15.5cm), we'll likely need to have the “front” section of insulation partially attached to the lid, going vertically down, with an angled transition so we can fit things in more easily (need to sketch this). Insulation is supposed to be 10cm/4in. all around.

The Isotherm's use a Danfoss BD35, dimensions of the compressor are: 10.63“ x 6.31” x 13“ or 27cm x 16cm x 33cm.

The manual for a 2006 specifies insulation of 5cm thickness for a 2.8 cu. ft. box, we'll have roughly a 2.6 cu. ft. box, so 5cm/2” thickness it is.

The locker:

Task break-down

Faucet replacement

replace last section of tubing to both faucets - need X size hose.install pressure switchinstall in-line disable/override switchadd breaker for water pump- add damper